Sipotek is a professional china automated optical inspection machine manufacturers located in shenzhen city,major products including visual inspection machine and automated optical inspection (AOI) machine.

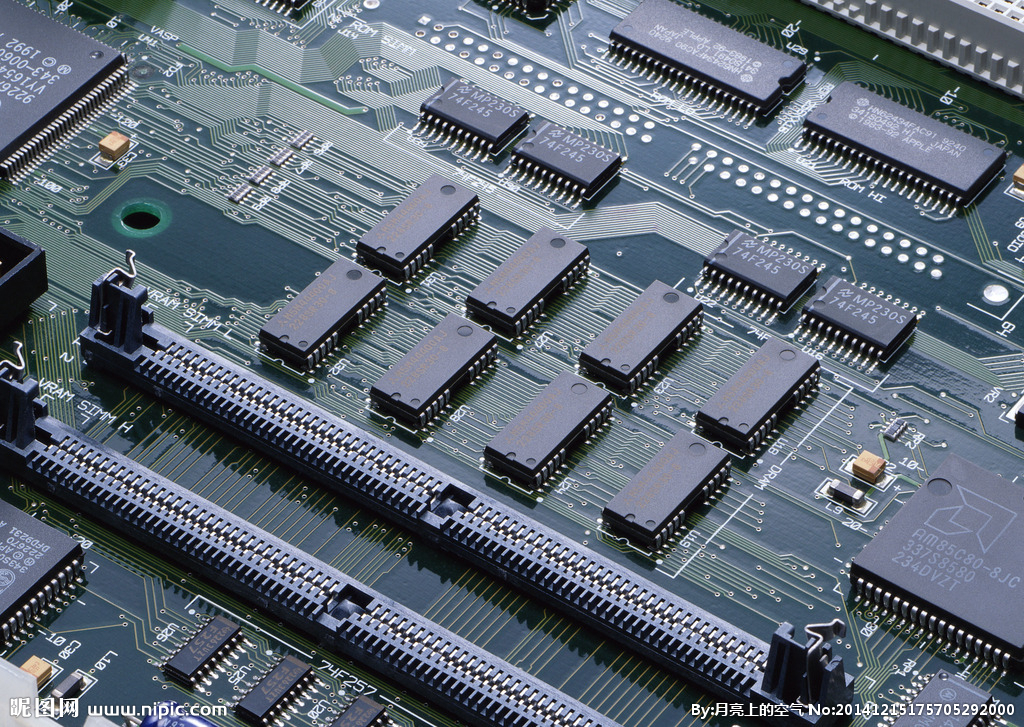

Today Sipotek will tell you something about the lighting kit for automated optical inspection machines and eqiupments sytems in circuit boards testing process.

When analyzing a circuit image, the Automated optical inspection, AOI system searches for various specific parameters: internal markers, component placement, component size, label templates (for example, barcodes), reflectivity and background color, etc. As an important part of its task, the AOI system also inspects welded joints to ensure that they indicate that the joints are satisfactory.

Now, when analyzing circuit boards, the AOI system must take into consideration many distinctions among the good circuit boards. Not only do components differ considerably in color, but also in size and reflectivity. There are also often screen printing differences where the ink thickness and color type may change a bit.

AOI light source

Lighting is a major part of the AOI system. By selecting the accurate light source, different types of defects can be more easily detected. Thanks to advances in lighting technology over the last few years, it has allowed us to use lighting to improve the available images and, thus, to highlight faults more easily, resulting in reduced necessary treatment and increased speed and precision.

Many AOI systems have a defined lighting package. This will depend on the operation need and the types of products to be tested. These were generally optimized for the expected conditions. However, sometimes personalization and understanding of lighting can always be helpful.

Different types of lighting are available:

Fluorescent Lighting: Now, fluorescent lighting is vastly used for AOI type automated optical inspection applications because it offers an effective form of illumination for displaying defects on printed circuit boards. The main problem with fluorescent lamps for AOI applications is that lamps break down over time. What this implies is that the automated optical inspection system will be subject to ever-changing light levels and quality.

LED lighting: The manufacture of LED lighting has enabled AOI automated optical inspection systems to adopt a more stabilized form of lighting. Although light-emitting diode lighting suffers from a reduction in light output over time, this increase can be offset by an increase in current. With the use of LED lighting, you can also control the lighting level. LEDs are therefore much more satisfactory lighting than incandescent or fluorescent lamps used in the past.

Ultraviolet or Infrared: In some cases, you may need ultraviolet or infrared lamps to improve some defects or to allow automatic optical control to detect certain types of defects.

In addition to the shape of the lighting, the positioning of the lighting for an automatic optical control system, AOI, is also important. Light sources must be positioned not only to ensure that all areas are well lit, which is especially important when some components may project shadows, but also to expose defects. For different mountings, careful adjustment might be necessary.

AOI, automatic programming of optical control system

In order to test a printed circuit board assembly using AOI, automated optical inspection, the details of an acceptable array must be stored in the system. This programming task must be performed correctly if the AOI system is meant to properly detect any faults on the PCBs being passed through.

Several methods can be used to program an AOI system:

Using “Golden Board”: A method used is to provide a circuit board called target for the automated optical inspection system(AOI). This went through the system so that it could learn the relevant attributes. Now, it will analyze the components, the welding profiles of each joint and many other aspects. To provide the system with enough data, several circuit boards are often needed.

Sipotek Technology has a variety of visual inspection machines that allow easy and quick detection of flaws in a product. They also have the single click detection machine that is easy to operate and is fast and efficient to perform testing. The machine is designed to shorten the inspection time and reduce the human error, while assembling or manufacturing a product. With its rapid detection technique, the machine software quickly matches the template and detects the defects or missing components. The company helps automate the manufacturing process and enables companies to stay competitive.

One can check the features of their inspection machines by visiting the website https://www.sipotek.net/ .

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Shenzhen Sipotek Technology Co., Ltd is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net

No comments:

Post a Comment